Pendant des décennies, le légendaire 5,9L 12 Valve Cummins (produit à peu près 1989-1998) a été l'épine dorsale d'innombrables micros, camions de travail, et applications industrielles. Vénéré pour sa simplicité brute, force brute, et nature presque indestructible, Garder ces moteurs en marche forte se résume souvent à une refonte appropriée. Choisir le bon kit de révision - Comprendre spécifiquement les composants critiques comme les pistons, culasses, injecteurs, et la pompe à injection - est primordial. Crotons-nous ce qui fait un kit de révision de qualité 12v Cummins Tick.

La fondation: Le 12 Kit de révision de Valve Cummins lui-même

Un vrai Kit de révision pour un Cummins 12V est plus qu'une simple boîte de joints. Un kit complet constitue les bases essentielles pour reconstruire les extrémités inférieures et supérieures. S'attendre à trouver:

– Piston & Kits de liner: Le cœur de la reconstruction (couvert en détail ci-dessous).

– Principal & Roulements de tige: Composants de précision pour restaurer le soutien du vilebrequin et le dégagement d'huile.

– Ensembles de joints: Vital pour sceller tout, du carter d'huile et du couvercle de soupape à la culasse et aux couvertures avant / arrière. Les kits de qualité incluent des joints critiques comme le joint principal arrière.

– Bouchons de congélation: Essentiel pour sceller les passages de liquide de refroidissement du bloc moteur.

– Anneaux de piston: Crucial pour le scellement de la compression et le contrôle de l'huile (Souvent inclus avec des pistons / doublures).

– Joints de tige de soupape: Empêcher l'huile de fuir les guides de soupape dans la chambre de combustion.

– Kit de vitesse de distribution: Assure un timing d'arbre à cames précis.

Sous le microscope: Caractéristiques des composants clés

1. Pistons: Le point de transfert de puissance

– Matériel & Conception: Les pistons de qualité sont généralement un alliage en aluminium forgé, offrant une résistance supérieure et une résistance à la chaleur par rapport aux pistons coulés, crucial pour gérer le couple 12V et les modifications potentielles. Recherchez des conceptions qui reproduisent ou améliorent le profil OEM.

– Revêtements: Les pistons de haut niveau présentent souvent des revêtements spécialisés:

— Revêtements de jupe (Par exemple, Moly, Graphite): Réduire les frictions pendant les démarrages à froid et minimiser les éraflures.

— Revêtements de couronne de barrière thermique: Aider à gérer les températures de la chambre de combustion extrême, réduire le transfert de chaleur dans le piston lui-même et empêcher les points chauds qui peuvent entraîner des fissures ou de la fusion.

– Rainures: Les rainures de précision assurent les sièges et la longévité des anneaux appropriés. Certains pistons de performance présentent des terres à anneaux plus épais pour une durabilité accrue sous des pressions de boost plus élevées.

– Hauteur de compression: Maintenir la bonne hauteur de compression (Distance entre le centre des épingles au poignet et la couronne de piston) est essentiel pour préserver le ratio de compression conçu du moteur et le dégagement du piston à soupape. Offres de pièces épides Cummins Pistons conçu pour les spécifications OEM exactes, y compris les options avec des revêtements de barrière thermique avancés pour les applications exigeantes.

2. Culasse: Respiration & Centre de scellement

– Qualité de coulée: La fondation est un casting sonore, exempt de porosité ou de changement de noyau. Les fournisseurs réputés proviennent souvent de Foundries avec des records de pistes éprouvés pour les têtes Cummins.

– Soupape & Travail de place: Une refonte de tête appropriée implique:

— Broyage / remplacement de la valve: Assurer les vannes siège parfaitement. Les kits de qualité peuvent inclure de nouvelles vannes ou les nécessiter séparément.

— Coupe / remplacement des sièges: Usinage ou remplacement des sièges de soupape durcis pour un joint parfait. Les travaux de soupape à trois angles sont standard pour un débit optimal et un scellement.

— Guide: La vérification et le remplacement des guides de soupape usés sont essentiels pour un bon alignement de la valve et la prévention de la consommation d'huile.

– Planéité de surface: La surface d'accouplement doit être méticuleusement usinée à plat pour assurer un joint parfait avec le joint de tête.

– Composants de précision: Ammeurs de rocker neufs ou reconditionnés, tirs (La vérification de la rectitude est vitale!), ponts, et les vis de réglage sont souvent nécessaires. Les pièces EPID offrent entièrement reconditionné culasses ou composants de tête essentiels comme les ensembles de soupapes et les surfaces de précision, Assurer un flux d'air optimal et une intégrité d'étanchéité pour vos kits de reconstruction 12V.

3. 12V Cummins Fuel Injecteurs: Livraison de carburant de précision

– Indicateur de la buse: Les pointes de la buse de l'injecteur sont essentielles. Les injecteurs révisés doivent avoir des buses qui fournissent un motif de pulvérisation atomisé parfait. Les buses usées mènent à une mauvaise combustion, fumée, réduction de la puissance, et dilution de carburant dans l'huile.

– Pression pop: La pression à laquelle l'ouverture de l'injecteur doit être réglée précisément selon les spécifications de Cummins pour un calendrier approprié et une livraison de carburant.

– Scellés & Composants: Tous les joints et composants internes doivent être remplacés lors de la reconditionnement pour éviter les fuites et assurer des performances cohérentes.

– Débit équilibré: Pour une douceur et une puissance optimales du moteur, Les injecteurs doivent être testés en débit et appariés comme un ensemble. Pièces EPID fournit des ensembles d'injecteurs remanufacturés testés rigoureusement et équilibrés, garantir la livraison précise de carburant votre 12 Valve Cummins demandes d'efficacité et de puissance maximales.

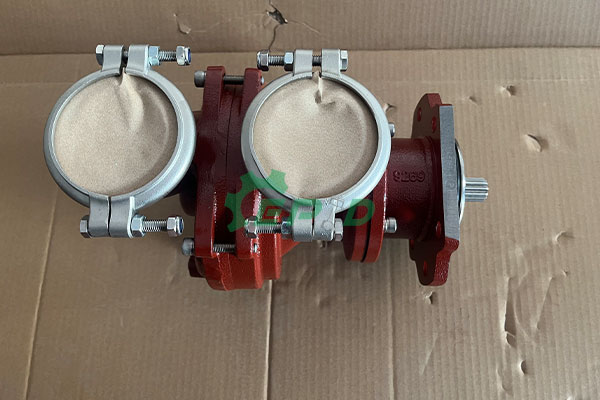

4. Pompe à injection: Le cœur mécanique (Ve ou p7100)

– La pompe ve (Début 12V): Bien que généralement fiable, sa conception rotative a des internes plus complexes. Une refonte de qualité consiste à remplacer les internes usés comme la tête hydraulique, bague à rouleau, et plaque de came, et le calibrer précisément.

– La pompe P7100 (Plus tard 12V – “P-Pump”): Le Saint Graal pour la simplicité et la régabilité de l'injection mécanique. La révision d'un P7100 se concentre sur le remplacement des plongeurs usés, barils, vannes de livraison, scellés, et le recalibrer aux spécifications exactes. La pression et le timing de carburant sont essentiels.

– Qualités: L'utilisation de pièces inférieures à la communauté ou un mauvais étalonnage dans l'une ou l'autre pompe entraîne de mauvaises performances, fumée, Début difficile, ou un échec prématuré. Les pièces épides comprennent le rôle critique de la pompe à injection. Ils offrent des pompes VE et P7100 remanufacturées de manière experte, reconstruit avec des composants de haute qualité et calibrés aux normes Cummins exigeantes pour fiable, Livraison de carburant puissante.

Parties épides: Votre partenaire dans 12V Cummins Rebirth

Reconstruire un légendaire 12 Valve Cummins n'est pas seulement des pièces; Il s'agit de confiance et d'expertise. Les pièces épides se démarquent en se concentrant sur les composants critiques qui font ou brisent une reconstruction:

– Pistons de précision: Offrir des options forgées avec des revêtements thermiques pour la durabilité sous pression.

– Expertise en culasse: Fournir des têtes reconditionnées ou les composants essentiels pour un travail de valve parfait et un sceau.

– Maîtrise du système de carburant: Fournir un flux assorti, injecteurs testés et pompes d'injection remanufacturées de manière experte (Ve ou p7100).

– Noyau de qualité: Utiliser des matériaux de haute qualité et adhérer à des processus de remise à neuf rigoureux.

– Support technique: Soutenir leurs pièces avec un soutien compétent pour votre voyage de reconstruction.

Conclusion: Investir dans la légende

Le 5,9L 12 Valve Cummins a acquis sa réputation pour une raison. Une refonte réussie de la révision sur la compréhension des nuances de ses composants centraux - des pistons construits pour résister à la furie de combustion, un 12 Valve Cummins Cylinder Usinée pour un scellage et un flux parfaits, Injecteurs livrant du carburant avec précision, et une pompe à injection calibrée pour une puissance fiable. Choisir un kit de révision 12v complet soutenu par des composants individuels de haute qualité est non négociable.

Les pièces EPID fournissent les éléments constitutifs essentiels - des pistons avancés et des culasses diesel méticuleusement reconditionnées vers des injecteurs équilibrés et des pompes d'injection reconstruites avec précision - garantissant votre 12 Valve Cummins Rebuild Kit n'est pas seulement une réparation, Mais un investissement dans des décennies plus de performance légendaire. Faites confiance au cœur de la bête, reconstruit à droite.