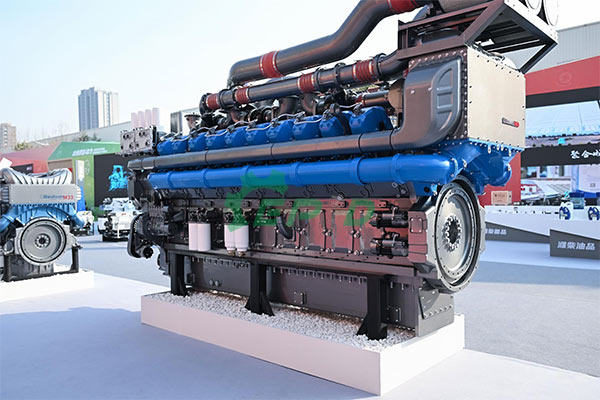

In industries where reliability and efficiency are non-negotiable—whether a construction site racing against deadlines, a long-haul truck navigating mountain roads, or a power plant keeping a city running—Weichai engines have become synonymous with durability and performance. However, even the most robust engines require meticulous maintenance, and the choice of spare parts can make or break operations. EPID Parts can ensure seamless access to high-quality components that keep these engines running optimally.

Understanding Weichai Engine Spare Parts: A Lifeline for Performance

Weichai engines power a wide range of machinery, from heavy-duty trucks to industrial generators. Their spare parts are categorized into three main types, each serving distinct needs:

1. Original Equipment Manufacturer (OEM) Parts

OEM parts are designed and produced by Weichai or its authorized partners, guaranteeing exact compatibility with specific engine models like the WP12, WD615, or WP10. These include critical components such as cylinder heads, turbochargers, pistons, and crankshafts. For instance, the WP12 engine’s turbocharger (model 61560116227) is engineered to handle high-pressure conditions in heavy trucks, ensuring fuel efficiency and reduced emissions. Using OEM parts minimizes downtime and aligns with Weichai’s rigorous performance standards.

2. Aftermarket Compatible Parts

Cost-effective alternatives to OEM parts, aftermarket components are ideal for budget-conscious operations without compromising quality. Reputable suppliers like EPID Parts produce filters, gaskets, bearings, and sensors that match Weichai’s specifications. For example, EPID’s marine-grade fuel filters protect WP-series engines in fishing vessels from saltwater corrosion, extending engine life at a fraction of OEM costs.

3. Performance-Upgrade Parts

For industries pushing engines beyond standard limits, specialized upgrades like high-flow fuel pumps or reinforced piston rings offer enhanced power and durability. Mining operations, for instance, rely on EPID’s heavy-duty air filters (model 612600113196) to prevent dust ingress in Weichai-powered excavators operating in arid environments.

Weichai Engines in Action: Powering Critical Industries

Weichai’s versatility shines across sectors, with specific engine models tailored to meet unique challenges:

1. Heavy-Duty Trucks and Logistics

The WD615 and WP12 engines dominate the trucking industry. Known for their high torque (up to 2,110 N·m) and fuel efficiency, these engines power long-haul vehicles like the Sinotruk HOWO. Key components such as timing gear housings (model 612600011783) and turbochargers ensure consistent performance under extreme loads. EPID’s rapid delivery of OEM-grade parts helps fleet managers minimize downtime during cross-country hauls.

2. Construction and Mining Equipment

In harsh environments, Weichai’s WP7 and WP10 engines drive bulldozers, excavators, and drilling rigs. Their rugged design withstands vibrations and dust, but components like weichai crankshafts and cylinder liners require regular replacement. EPID’s Weichai overhaul gasket kits (model D9) simplify maintenance for equipment operators, ensuring engines endure 24/7 operations.

3. Power Generation and Backup Systems

Weichai’s WD12G series engines are trusted in remote power plants and emergency backup systems. These engines support biodiesel compatibility, aligning with sustainable energy goals. Critical parts like weichai fuel injection pumps (model 612601080844) and voltage regulators (model 612600090259) from EPID ensure uninterrupted power supply, even in off-grid locations.

4. Agricultural Machinery

From tractors to irrigation pumps, Weichai’s WP6G engines deliver reliable power for farming. EPID’s dust-proof alternators and cooling radiators protect engines from mud and debris, crucial during harvest seasons when downtime translates to financial losses.

EPID Parts: Elevating Weichai Engine Maintenance

In a market flooded with suppliers, EPID Parts stands out by bridging the gap between affordability and uncompromising quality:

– Quality Assurance: EPID’s diesel engine parts, such as turbochargers (model HTHX50) and cylinder head assemblies, undergo ISO-certified testing to meet or exceed Weichai’s benchmarks.

– Comprehensive Inventory: With over 75 Weichai-specific parts in stock—from thermostat assemblies (615G00060016) to belt tensioners (1001319530)—EPID reduces lead times for urgent repairs.

– Technical Support: EPID’s engineers assist customers in selecting the right parts, troubleshooting issues, and optimizing maintenance schedules. A mining company in Australia, for example, credits EPID’s guidance for reducing engine failures by 40%.

– Global Reach: Strategically located warehouses enable EPID to deliver parts like fuel filters and water pumps to clients worldwide within days, even for niche models like the WD618.

Conclusion: Sustaining Excellence with the Right Partners

Weichai engines are the backbone of industries that keep economies moving, but their longevity hinges on using the right spare parts. Whether it’s an OEM turbocharger for a WP12 engine or an aftermarket filter for a WD615, every component plays a role in maintaining efficiency and reducing operational risks.

EPID Parts emerges as a critical ally in this ecosystem, offering not just parts but solutions—combining technical expertise, global logistics, and a commitment to quality. For a construction firm racing against project deadlines or a hospital relying on backup power, choosing EPID means investing in reliability, sustainability, and peace of mind.